Why Temperature Control is Business-Critical

In cold chain logistics, quality loss isn’t just a customer issue—it’s a direct threat to your bottom line. For sensitive goods ranging from meat and seafood to vaccines, maintaining stable temperatures and ensuring fast handovers are the two factors that determine the success of your shipment.

Practical Cold Chain Design

An effective cold chain operation requires meticulous planning and execution:

- Pre-cooling and Packaging: Goods must be pre-cooled to the required temperature and packaged appropriately for the duration of the journey.

- Reefer Container Set-Points: The correct temperature set-points must be confirmed with the shipping line and verified before departure.

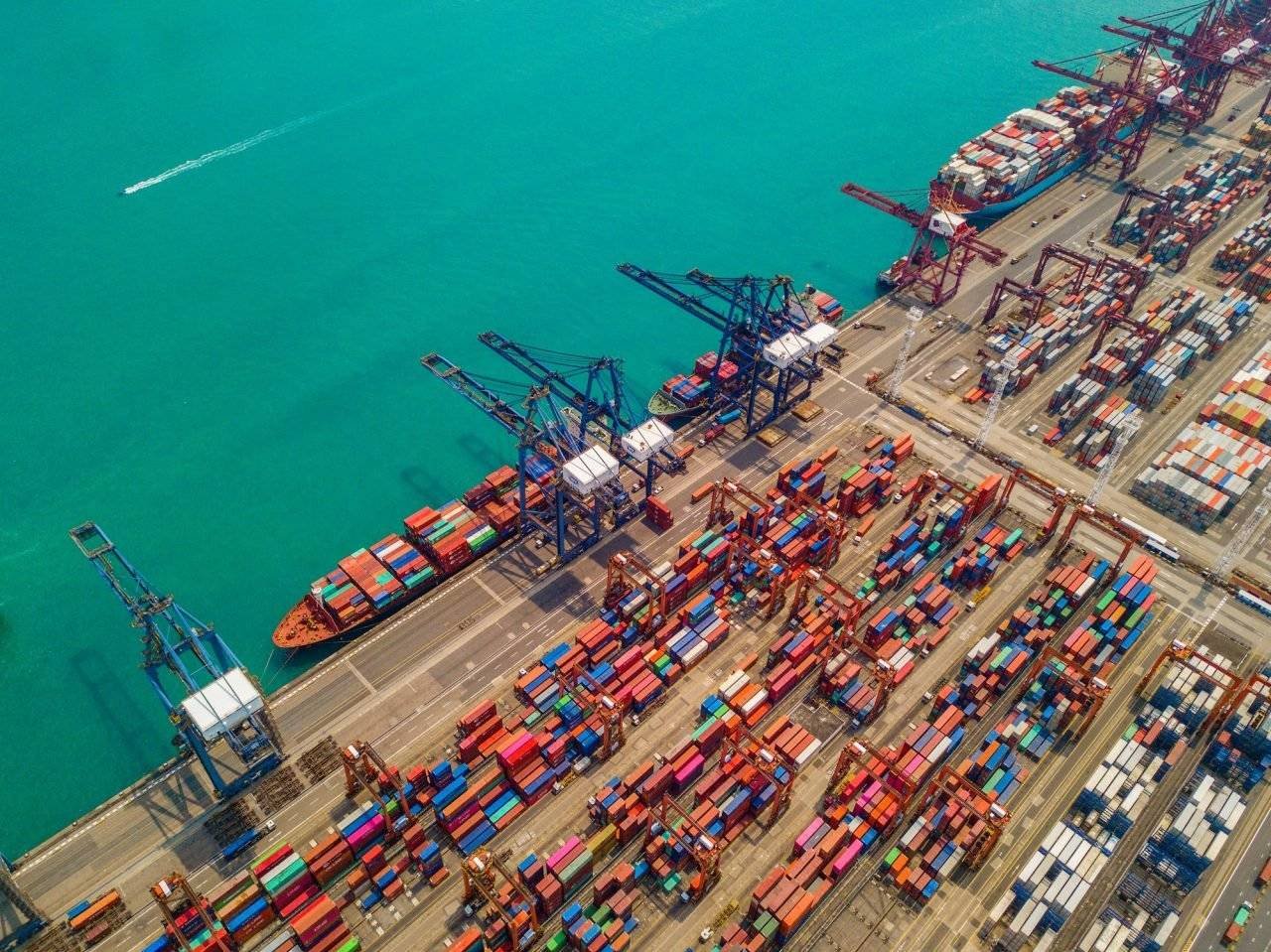

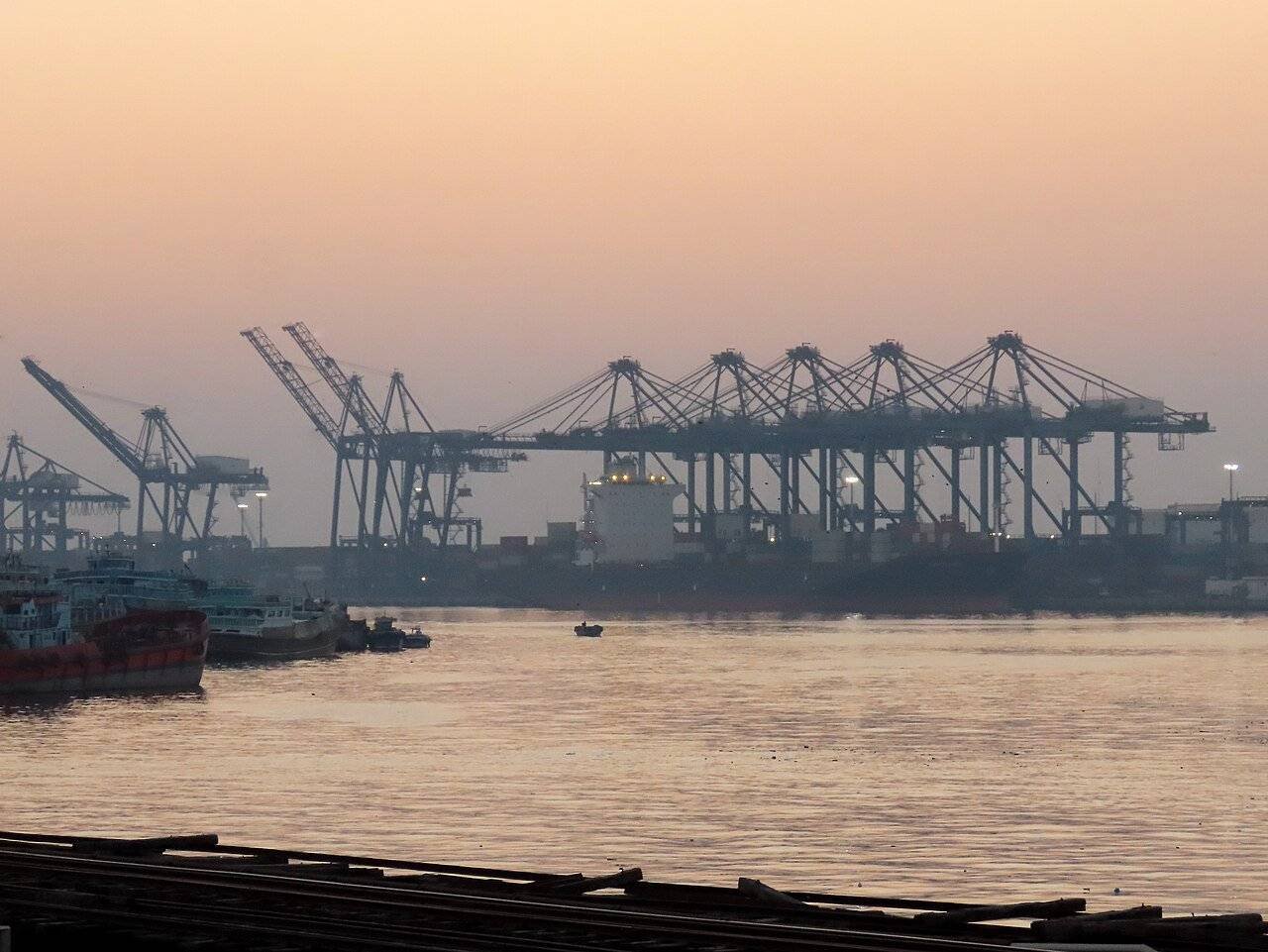

- Priority Handling: To minimize the time the reefer is powered off, we ensure priority gate-in and gate-out at terminals.

- Trained Handlers: All transfers, especially at cold-room facilities, are handled by trained personnel to prevent temperature excursions.

UTradeShipping’s Approach

We provide a robust cold chain solution designed for reliability:

- We conduct lane studies to identify ambient and seasonal risks for each route.

- We offer set-point validation and support for data loggers to monitor temperatures throughout transit.

- Our temperature exception protocol and claim documentation process are designed to protect your interests in case of an incident.

Pharma Considerations

For pharmaceutical products, the stakes are even higher. We manage pharma logistics with specific considerations in mind:

- GDP-Aligned Handling: Our processes and SOPs are aligned with Good Distribution Practices (GDP).

- Chain-of-Custody Records: We maintain meticulous records to ensure a clear chain of custody.

- Contingency Planning: We have protocols in place to handle unexpected power or plug issues at terminals, safeguarding your critical cargo.